Andrews, Jordan: Assessing the Environmental Impact of Various Fabrication Methods for Organic Photovoltaics

Title: Assessing the Environmental Impact of Various Fabrication Methods for Organic Photovoltaics

Name: Jordan Andrews

Home Institute: Amherst College

Programs: RISE program, REU – Green Energy Technology Undergraduate Program (GET UP)

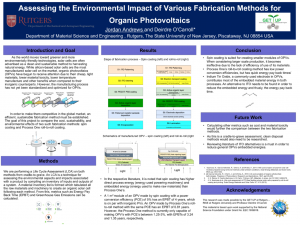

Other contributors: Deirdre O’Carroll

Abstract: As the world moves toward greener and more environmentally friendly technologies, solar cells are often advertised as a clean and sustainable method to harvesting natural energy. While silicon-based solar cells are the most manufactured solar cell on the market, organic photovoltaics (OPVs) have begun to receive attention due to their cheap, light materials, lower material toxicity, lower temperature manufacture and other benefits when compared to their inorganic counterparts. However, the manufacturing process has not yet been standardized and optimized for OPVs. In order to make them competitive in the global market, an efficient, sustainable fabrication method must be established. In addition, the power conversion efficiency is at best 16% which is far lower than silicon devices (>25%). So far, numerous methods have been developed for the fabrication of OPVs, but few studies have directly compared them. The goal of this project to compare the sustainability and environmental effects of two such fabrication methods: spin coating and roll-to-roll. To that end, a Life Cycle Assessment (LCA) is performed on both methods from cradle-to-grave. A cradle-to-grave assessment examines the energies in all raw materials, machinery, and processes required to make the OPV, the amount of energy the OPV will generate in its lifetime, and the energy produced in the product’s disposal.

To ensure the processes are properly compared, the finished OPV must be standardized. The “Process One” [1] roll-to-roll method and spin coating [2] create slightly different OPVs. To account for this, the spin coating method is adjusted to create the same solar cell structure as the Process One method. The next step for the LCAs is creating an inventory list for both processes that accounts for the energy and cost (per gram) associated with the raw materials, components, and machinery used as well as the byproducts such as waste and greenhouse gases. Subsequently, these quantities will be used in calculating the energy payback time (EPBT), GHG (greenhouse gas) emissions, and overall cost of production. These values for both processes will be compared to determine the more sustainable method.

Biography: Jordan Andrews is a rising senior at Amherst College, where he is a Chemistry and Computer Science double major. He was born in Hoboken, New Jersey, and he has always been interested in learning and STEM related activities. Throughout high school, Jordan was able to funnel down his interest in the sciences through trial and error and found that he was adept at Chemistry. In the summer of 2017, Jordan became an American Chemical Society Scholar and was awarded a scholarship to major in chemistry. Through the privilege of attending an institution like Amherst, he was able to explore many different avenues of learning while taking his Chemistry courses. In the summer of 2019, he researched under Professor David Hansen, where he studied the synthesis of naphthalene diimide (NDI) derivates using artificial amino acids and spectroscopy. NDI form nanotubes in solution through helium bonds, and Jordan studied the possibility of creating biodegradable plastics through appending polymer chains onto these tubes. Currently, he is studying under Dr. Deidre O’Carroll in her Materials and Engineering lab where he is performing a life cycle analysis on different fabrication methods of organic photovoltaics. In the future, Jordan plans to work in industry before furthering his education in graduate school.