Mechanistic Model Development & Validation of Particulate Processes

Here, we seek to develop mechanistic and predictive models of particulate processes such as granulation, mixing, and milling. We are working to develop sub-models (kernels) that describe the dynamics as a function of key material properties and process parameters. The models are validated against experimental data at the lab scale and are tested for their predictive capability. Such validated models are able to reduce the time and cost associated with tedious experimental trials.

Batch Processes

Batch Processes

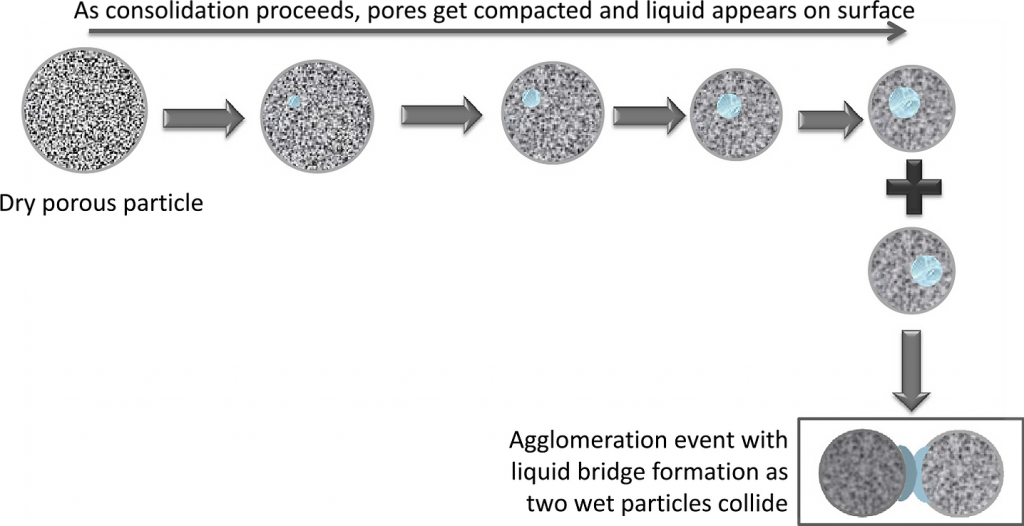

High Shear Granulation

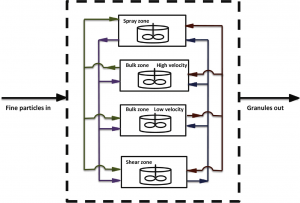

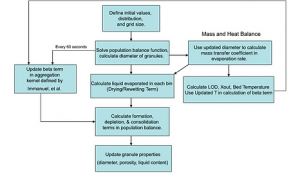

Fluid Bed Granulation

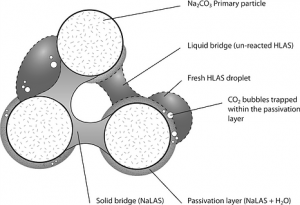

Reactive Granulation

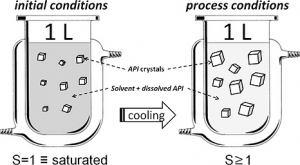

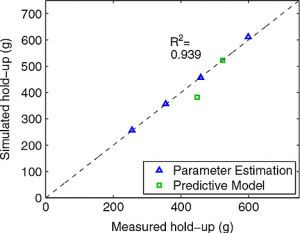

Crystallization

Continuous Processes

Drum Granulation

Mixing

Twin Screw Granulation

Milling

-

- A. Chaudhury, A. Tamrakar, M. Schongut, D. Smrcka, F. Stepanek, R. Ramachandran. Multi-dimensional population balance model development and validation of reactive granulation processes.Industrial & Engineering Chemistry Research , 54 (3), 842-857, 2015.

- D. Barrasso, A. El Hagrasy, J.D. Litster, R. Ramachandran. Multi-dimensional population balance model development and validation for a twin screw granulation process, Powder Technology, 270 B, 612-621, 2015.

- M. O. Besenhard, A. Chaudhury, T. Vetter, R. Ramachandran, J. Khinast. Evaluation of parameter estimation methods for crystallization processes modeled via population balance equations. Chemical Engineering Research & Design, 94, 275-289, 2015.

- A. Chaudhury, M. E. Armenante and R. Ramachandran. Compartment based population balance modeling of a high shear wet granulation process using data analytics. Chemical Engineering Research & Design, 95, 211-228, 2015.

- M. Sen, A. Chaudhury. R. Singh, R. Ramachandran. Two-dimensional population balance development and validation of a pharmaceutical crystallization process. American Journal of Modern Chemical Engineering, 1, 3-29 , 2014.

- A. Chaudhury, D. Barrasso, P. Pandey, H. Wu, R. Ramachandran. Population balance model development, validation and prediction of CQAs of a high-shear wet granulation process: Towards QbD in drug product pharmaceutical manufacturing, Journal of Pharmaceutical Innovation, 9 (1), 53-64, 2014.

- A. Chaudhury, H. Wu, M. Khan, R. Ramachandran. A mechanistic population balance model for granulation processes: Effect of process and formulation parameters, Chemical Engineering Science, 107, 76-92, 2013.

- D. Barrasso, S. Oka, A. Muliadi, J.D. Litster, C. Wassgren and R. Ramachandran. Population balance model validation and prediction of CQAs for continuous milling processes: toward QbD in pharmaceutical drug product manufacturing. Journal of Pharmaceutical Innovation, 8(3), 147-162, 2013.

- D. Barrasso, S. Walia, R. Ramachandran. Multi-component population balance modeling of continuous granulation processes: a parametric study and comparison with experimental trends. Powder Technology, 241, 85-97, 2013.

- A. Chaudhury and R. Ramachandran. Integrated population balance model development and validation of a granulation process. Particulate Science & Technology, 31(4), 407-418, 2013.

- A. Chaudhury, A. Niziolek and R. Ramachandran. Multi-dimensional mechanistic modeling of fluid-bed granulation processes: an integrated approach. Advanced Powder Technology, 113-131, 24, 2013.

- M. Sen and R. Ramachandran. A Multi-dimensional Population Balance Model Approach to Continuous Powder Mixing Processes. Advanced Powder Technology, 51-59, 24, 2013.

- M. Sen, R. Singh, A. Vanarase, J. John and R. Ramachandran. Multi-dimensional population balance modeling and experimental validation of continuous powder mixing processes. Chemical Engineering Science, 80, 349-360, 2012.

- P. Pandey, J. Tao, A. Chaudhury, R. Ramachandran, J.Z. Gao, D. Bindra. A combined experimental and modeling approach to study the effects of high-shear wet granulation process parameters on granule characteristics.Pharmaceutical Development & Technology, 18, 210-224, 2012.

- R. Ramachandran, M. Ansari, A. Chaudhury, A. Kapadia, A. V. Prakash and F. Stepanek. A quantitative assessment of the influence of primary particle size distribution on granule inhomogeneity. Chemical Engineering Science, 104-110, 71, 2012.

- R. Ramachandran and A. Chaudhury. Model-based Design and Control of Continuous Drum Granulation Processes. Chemical Engineering Research & Design, 90, 1063-1073, 2012.

- F. Boukoulava, A. Dubey, A. Vanarase, R. Ramachandran, F.J. Muzzio and M.I. Ierapetritou. Computational approaches for studying the granular dynamics of continuous blending processes: Population Balance and Data based methods. Macromolecular Materials and Engineering, 296, 9-19, 2012.