Multi-scale Model Development of Particulate Processes

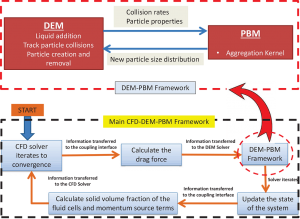

In scaling up to the pilot-plant or industrial scale it is important to formulate a formal link to the macro-scale phenomena (critical quality attributes of particles) by incorporating micro-scale phenomena (particle velocities, collision frequency), meso-scale phenomena (particle aggregation, breakage etc.), together with effect of process parameters, material properties and equipment geometry. We use a combination of population balances, discrete element models and computational fluid dynamics to elucidate and study this behavior.

Twin Screw Granulation

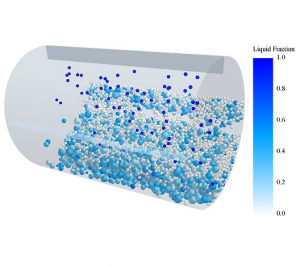

Drum Granulation

Fluid Bed Granulation

Multi-scale DEM-PBM Coupled Simulation of Twin Screw Granulation Processes

DEM Simulation of Drum Granulation Processes

-

- D. Barrasso and R. Ramachandran. Qualitative assessment of a multi-scale, compartmental PBM-DEM model of a continuous twin-screw wet granulation process. Journal of Pharmaceutical Innovation, 1-19, 2015.

- D. Barrasso, A. Tamrakar, R. Ramachandran. Model order reduction of a multi-scale PBM-DEM description of a wet granulation process via ANN. Procedia Engineering, 102, 1295-1304, 2015.

- D. Barrasso, T. Eppinger, F. Perera, R. Aglave, K. Debus, S. Bermingham, R. Ramachandran. A multi-scale, mechanistic model of a wet granulation process using a novel bi-directional PBM-DEM coupling algorithm.Chemical Engineering Science, 123, 500-513, 2015.

- D. Barrasso, R. Ramachandran. Multi-scale modeling of granulation processes: Bi-directional coupling of PBM with DEM via collision frequencies. Chemical Engineering Research & Design, 93, 304-317, 2015.

- M. Sen, D. Barrasso, R. Singh, R. Ramachandran. A Multi-scale Hybrid CFD-DEM-PBM Description of a Fluid-bed Granulation Process. Processes, 2 (1), 89-111, 2014.

- M. Sen, A. Dubey, R. Singh, R. Ramachandran. Hybrid PBM-DEM simulation and validation of a continuous mixing process. Journal of Powder Technology, 2013, 1-11, 2013.

- R. Ramachandran. A multi-scale approach to granulation process design. Computer Aided Chemical Engineering, 29, 9-19, 2011.