Today is a good, cold day in New Jersey, so I’ve turned the thermostat down to about 10C and am making up a batch of blue verditer. I’ve been working on eighteenth-century color, one pigment at a time– focusing especially on the colors Robert Dossie mentions as good for marbling. It isn’t just that the second edition of Dossie’s Handmaid of the Arts (1764) is the best authority on marbling in the eighteenth century, which it is. It is also likely that Dossie learned the art from one of the very people involved in making the motley emblem. Verditer is one candidate he mentions for the greens. It is also the first mineral pigment I’ll be synthesizing as part of this project– the others so far all being from botanicals. I’ll be experimenting with verditers over the next week or so.

Verditer is a name for the synthetic form of the cupric mineral azurite, which, in its natural form, had been known as “bice” since at least the sixteenth century (i.e. Bristow, 17). Verditer is from verd de terre, which is “green of the earth” in French, but the best verditers in eighteenth-century Europe were from England. Also, the best verditers were the blue ones. For reasons I’ll hope to write in a chapter on green, there are few good true green pigments, so the color-men often relied on mixtures of blues and yellows. One such well-known combination was, recorded by Thomas Jenner in 1652, was to mix verditer with a yellow pigment called “pink”. “Blew Verditer,” he writes, is “a very bright pleasant blew… and being mixed with yellow-berries [i.e. “pink”] it makes a good green.” This is the combination repeated by Dossie.

The natural form of bice was an expensive pigment, not much used. But sometime around the seventeenth century it was discovered that one of the waste products of the refining industry, a leftover from the process called “parting,” was chemically identical. The metallurgists used aqua fortis to “part” gold from silver, then silver from copper, which were often found naturally mixed in the ores from mines in Cornwall and other places in England. The silver precipitates out, leaving copper in solution. The resulting solution, essentially an industrial waste product, can be further precipitated on chalk to produce a sea-green pigment. The earliest description of the last phases of the process is provided by the chemist Robert Boyle, writing in 1661:

… because by this manner of proceeding much Copper is wont… to remain in the Menstruum, … they are wont to pour it upon what they call Whiting… wherewith the tincted parts incorporating themselves, will in some hours, constitute a sort of Verditer fit for the use of Painters, and such other Artificers as deal in Colours.

I mentioned that the best verditer was from England; this is possibly the only dye for which this was true. It was English refiners who worked out the process and popularized the pigment, which was sometimes called “refiner’s verditer.” But it remained a puzzle, even to some refiners, why most batches would turn out green, while, on rare occasions, that green precipitate would turn out a brilliant blue, nearly as brilliant as the blue called “ultramarine,” the “overseas” pigment made from crushed lapis lazuli. Christopher Merrit, in a contemporary treatise on the manufacture of glass, calls it “a strange and great mystery to see how small and undiscernible a nicety… makes the one and the other colour.”

This was a problem from a commercial point of view; the blue pigments fetched a “manifold greater value,” Merrit remarks, selling for roughly five times what could be gotten for the green. It was also a puzzle from an academic perspective. Robert Boyle himself could not discover the cause. His remarks on verditer are in fact in an essay “On Unsucceeding Experiments,” where he reflects on the vanishingly small differences that seem to separate greens from blues. And the industrial chemists who produced the dyes were not forthcoming, either because they themselves did not know, or because it remained a valuable trade secret.

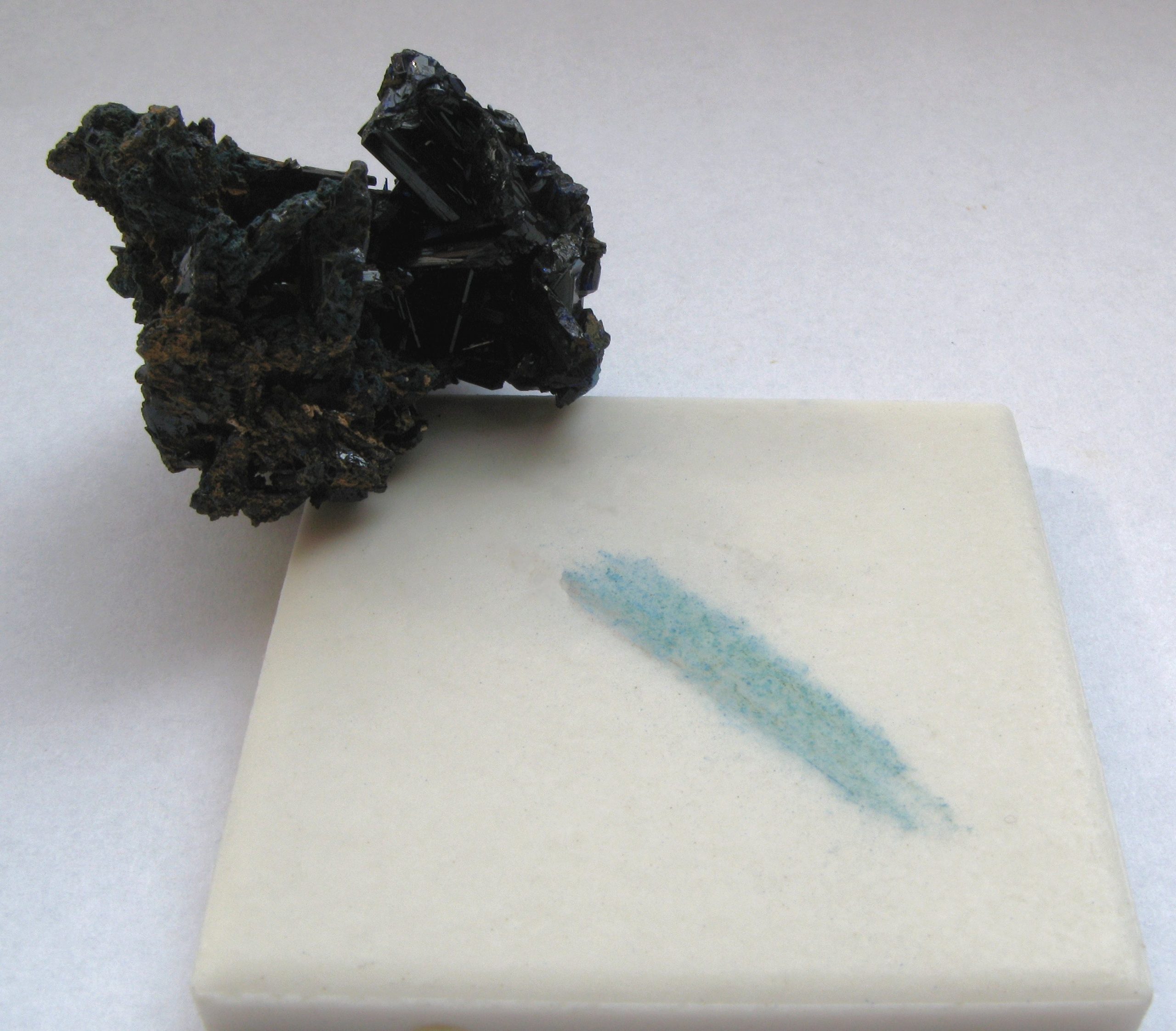

Since then, however, the mystery has been pierced. In the 1980’s, the chemists Peter and Ann MacTaggart, working in a makeshift alchemical laboratory, worked out the conditions reliably to produce verditers of the blue sort. The compositions, they found, are chemically identical, I mean in an analytical sense. It is their molecular microstructure that is different. The blue verditers are composed of much smaller particles of precipitate, of “tiny, rounded, fibrous aggregates,” much tinier in the blue than the green [Gettens and Stout]. To producing the bluer dyes is done by slowing down the precipitating chemical reaction. “Most of the authors’ successful experiments,” write MacTaggart and MacTaggart, “were carried out in a cellar during the early part of 1979, and they were finally halted by a run of warm days.” It is suspected that the historical blues were the byproduct of the parting process during the winter months, and the greens from the rest of the year, since the blues result when the temperature is less than about 12C.

For those of you who are interested, here’s a recipe. Robert Dossie suggests beginning by dissolving copper filings in nitric acid; a safer alternative is to begin with aqueous copper nitrate.

RECEIPT for BLUE VERDITER, or BICE

Take of copper nitrate fifteen grams, and dissolve in two-hundred milliliters of clear fountain water. Grind six grams of chalk to powder, until it be impalpably fine. Stir the chalk slowly into the copper nitrate solution; continue stirring for one minute, then allow to settle. For the first day, repeat stirring for one minute every half-hour, allowing again to settle. On the second day, stir once every four hours, until the parting fluid be nearly clear. Pour off the remaining fluid, which can be used again for parting. Wash well the remaining precipitate, and spread on boards to dry.

NB: For a deeper color, the same procedure may be repeated, this time adding the powdered verditer to the solution after the first mixture of copper nitrate and chalk is achieved.