(Continued from Prussian Green and The Wind Furnace)

Modern Prussian Blue is light-fast, chemically inert, and chromatically rich, so much so that it is still on modern painters’ palettes, for artists in oils and watercolors. When Bob Ross loaded up his palette, he always included Prussian Blue, which he favored for winter skies. It is also cheap, because easy to manufacture. For this reason, it was the blue used in blueprints, and, by the late nineteenth century, was the standard blue in Japanese blue woodblock prints. Hokusai’s Great Wave is one such print. It is also one of the last pigments which is also a medicine. The very word drug used to refer equally to pigments and medicines; it is now just about only Prussian Blue which is still part of the standard medical toolkit. Prussian Blue is used in histology, as a non-toxic stain for soft tissues, and as a remedy or cure for forms of radiation poisoning, taken in pill form. Other drugs can perform these functions; it is just that Prussian Blue is easy to make.

None of this was true, however, for the eighteenth-century version of the pigment, which was tricky to synthesize, contained a lot of impurities, and gave a surprisingly small yield for a lot of finicky work. It is true that it started showing up almost immediately after its discovery for paintings in oils. Watteau is known to have used it as early as 1710– just a few years after its discovery– and, by the end of the century, it was a regular feature of artists working in oils, on the palettes of both Thomas Gainsborough and Joshua Reynolds. But this is because it was a satisfactory replacement for ultramarine, the pigment which had to be extracted, in small quantities and with backbreaking labor, from lapis lazuli seams in the marble-faces of the Hindu Kush; as one sign of the rarity of ultramarine, the contracts drawn up between wealthy patrons and the painters of the Italian Quattrocento often spelled out exactly the type and quantity to be used in a commission (the other reagent so singled out was gold). But it was only in the nineteenth century that the techniques were worked out to synthesize Prussian Blue on a scale and cheapness that it could be used, for instance, for dyeing textiles. It is one of the persistent misprisions surrounding the pigment that its name comes from the color of the uniforms of the Prussian infantry. This is demonstrably false, since it was being called by that name within years of its invention. And I have found no evidence that the blue coats of the eighteenth-century Prussian army were dyed with the blue pigment called Prussian Blue, though the phrase “Prussian blue,” sometimes in quotes, has been used by twentieth-century military historians to describe the indigo hue which was standard across their infantry.

The modern way of manufacturing the pigment involves synthesizing it directly from some form of hexacyanoferrate; hexacyanoferrate is one iron atom bound with six cyanide molecules radiating equidistantly from it, like the tiny metal doodads scooped up in the children’s game called “jacks.” These are snapped into a theoretically endless lattice, the point of each hexacynoferrate compound lining up with a point of another, which are locked into place by iron ions with a different charge. So: if we were to describe what we saw along any single axis, we would see iron(II), cyanide, iron(III), cyanide, iron(II), and so on.

Neither of the precursors to Prussian Blue is blue. And, though the very word “cyanide” comes from the Greek word meaning “blue,” this proves to be a backformation from Prussian Blue; in roughly 1750, cyanide was isolated as its own (deadly) compound by cracking it out of the pigment, and named “blue” despite the fact that it is nearly colorless. Hexacyanoferrate therefore has the very word “blue” in its name, though, by itself, it is hardly blue at all.

Understanding the color of Prussian Blue requires a short detour. I have become interested, lately, in situations where a whole is different from the sum of its parts– and that is the case with Prussian Blue, where blueness is an emergent effect of combination. The iron in Prussian Blue is in two different oxidation states– which is to say, has two different numbers of electrons. As iron(II), it has given up two electrons, and is a dark brown color. Iron(III) is rust-red, precisely because rust is mostly composed of iron in that third oxidation state. The ability of iron easily to switch between oxidation states happens to be what makes it crucial to blood– and makes blood visibly different when oxygenated. When the iron(II) in hemoglobin forms a bond with oxygen, it gives up an electron to become iron(III); it changes its oxidation state, and becomes bright red. That same compound will later give up its oxygen to a cell which needs it, reclaiming its electron and reverting to duller, darker color gained from iron(II)..

The blueness only happens when both ions are locked in close proximity, from a special process called intervalence charge transfer. When hit with light of the right wavelength, some of the iron(II) ions throw off an electron, which is captured by a neighboring iron(III). Though the individual atoms stay locked in the lattice, the ions switch places, one shedding an electron, which the other gains. Because the compound absorbs only the precise orange wavelength that triggers the charge transfer, it reflects everything else. In white light, our eyes register the sum of the reflection as blue. Its ability to switch oxidation states internally therefore accounts for its chromatic richness. It is also what has made Prussian Blue a promising material in semiconductor and battery applications, as a window coating which changes properties in different light levels, and so on.

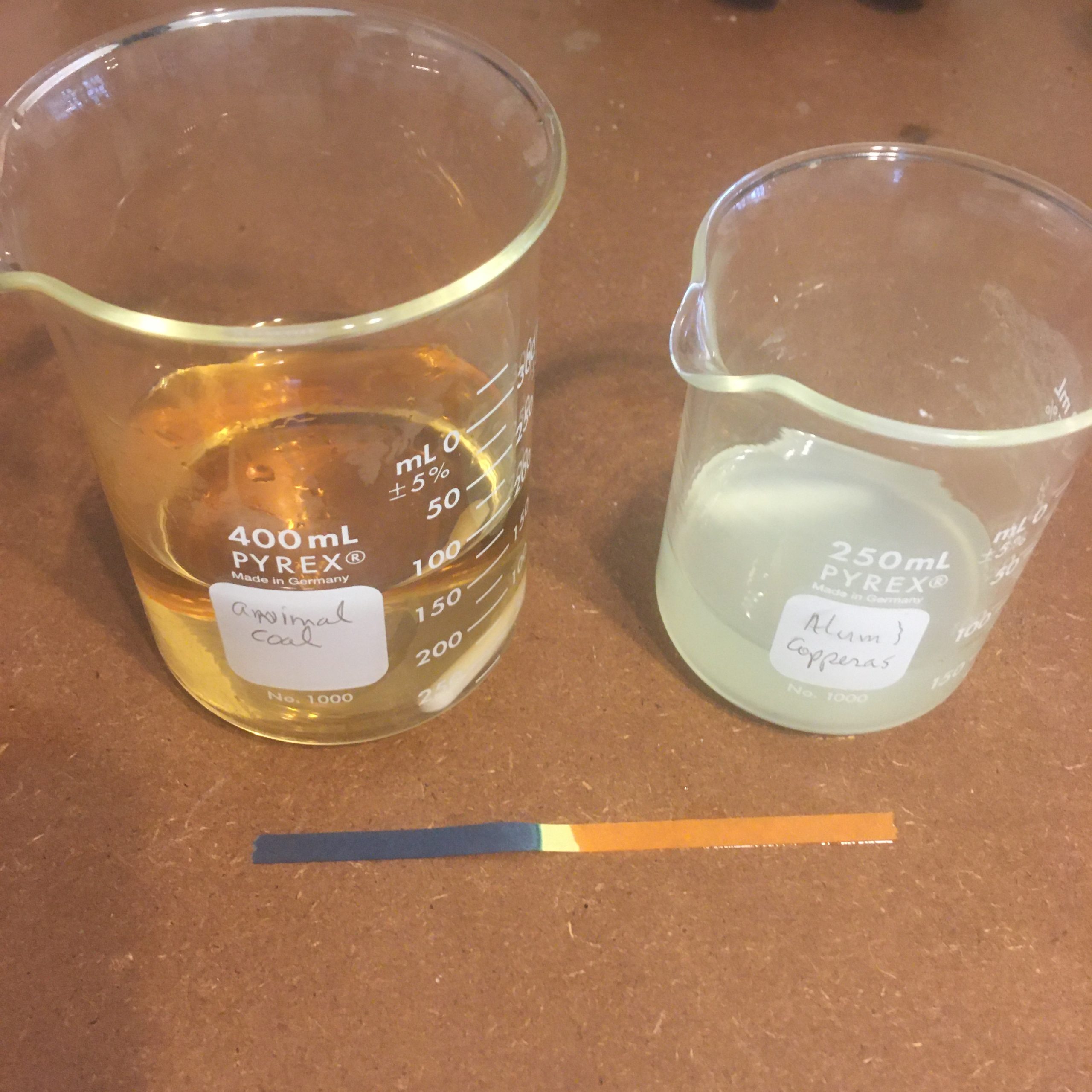

The chemistry between modern Prussian Blue and the eighteenth-century variety is similar. But where the modern process is direct, the eighteenth-century method was messy and inefficient, since it required iron(III) from blood, iron(II) from a synthesized compound called copperas, and an additional dose of potassium, which it had from wood ash. Though iron is the crucial element of hemoglobin, blood is still mostly composed of other elements. Isolating the iron, therefore, involves reducing a lot of blood to coal—leaving an imperfect powder of hexacyanoferrate, plus lots of carbon, loose iron ions, and other impurities.

The same was true for that other major chemical component—potassium—which, if I understand the chemistry correctly, both fills the bonds left empty where iron(III) is absent, and persists, with water, in some of the spaces left empty in the lattice-like structure of the hexacyanoferrate compound. I hope to have time to explore the history of potash in another post; the very name “potassium” remembers “pot-ash,” the lye isolated by soaking ashes in a deep vessel (like a pot). But that, too, is wasteful process. Wood reduced to 1 and 5% of its weight after being burned to ash, just 5% of which is potassium—so under even the best conditions, a kilogram of wood, burned, yields just a couple of grams of potash.

By the time the eye could see the color we call Prussian Blue, then, there required the combination of two reagents which were labor- and materials-intensive. This mixture, combined with copperas, produces Prussian Green, which is really only Prussian Blue with a few amorphous iron(III) ions in the mix. Cleaning that up is the last step in the process. Adding a few drops of hydrochloric acid transforms those loose iron ions into salts, and, since salts are soluble, they are poured off or filtered out, leaving behind miniscule clumps of blue pigment suspended in solution.

The yield from all this work is dispiritingly low. By comparison, four grams of cochineal, plus two grams or so of alum and another two of chalk to precipitate it upon—yields about three or four grams of cochineal pink. But sixty grams of blood, plus however many grams of vegetable matter are reduced to make five grams of potash, gives a little over a gram of Prussian Blue. The yield was so small that I lost most of my first batch in the paper I used to filter it from solution. With later batches, I instead followed John Woodward’s directions to “levigate” the separated solution; once the precipitate sinks to the bottom, I carefully pour off most of the clear lixivium. This process must be repeated several times to wash out the iron salts, but after three or four cycles, the resulting paste is scooped onto a plate and placed in the evaporator to dry. (During the winter months, my evaporator is the top of a radiator; during the summer, New Jersey weather does the trick.)